The FDA would require proof that the process of steeping (tea) or roasting/brewing (coffee) would eliminate potential microbiological threats.

Question: Are there any effective kill steps for the coffee roaster, consumer or tea consumer considering the commodity (tea) and processed commodity (roasted coffee) may have been served after having added water that approaches the boiling point?Īnswer: There is no FDA approved kill step for coffee or tea at this time. Note: “Tea leaves” are NOT included in the list mentioned above – there is NO specific exclusion of tea from any of the food safety regulations. Language around exclusions for coffee beans indicate that they must go through a “kill step” such as the roasting operation or process, before consumption… but a food processor who then takes the roasted coffee beans and uses them as an ingredient to make a “cold brewed coffee beverage” would be subject to all of the same Food Safety regulations as any other food processor because they are handling / processing the ingredient AFTER the “kill step” where it could become unsafe for consumption from environmental exposure.

Question: Are coffee beans included / covered in the new FSMA regulations?Īnswer: Coffee beans are listed as “rarely consumed raw” and excluded from being subject the Produce Regulations, however, they are NOT excluded from the Good Manufacturing Practices regulations or requirement for processing in a sanitary environment. I don't think much more is necessary, but can't find anything more concrete, source-wise, to validate my position (unlike, say, the thermal processed acidified Chai products our sister company does, which I also supervise, and which has clear FDA guidelines re: acidification, temperature, etc., and we have our process authority letter,etc.).Īm I just being paranoid, or amI missing something in regards to the coffee roasting and packaging process? We have GMPs, we have Sanitation, Chemical, and Allergen controls (which I'm aiming to strengthen), but is there anything else I should worry about? I do routine swabs for salmonella in processing areas, but not on Zone 1 equipment, since that would necessitate precautionary holds.

#WHY SPECIALIZED FOOD PROCESSING METHODS REQUIRE HACCP PLAN VERIFICATION#

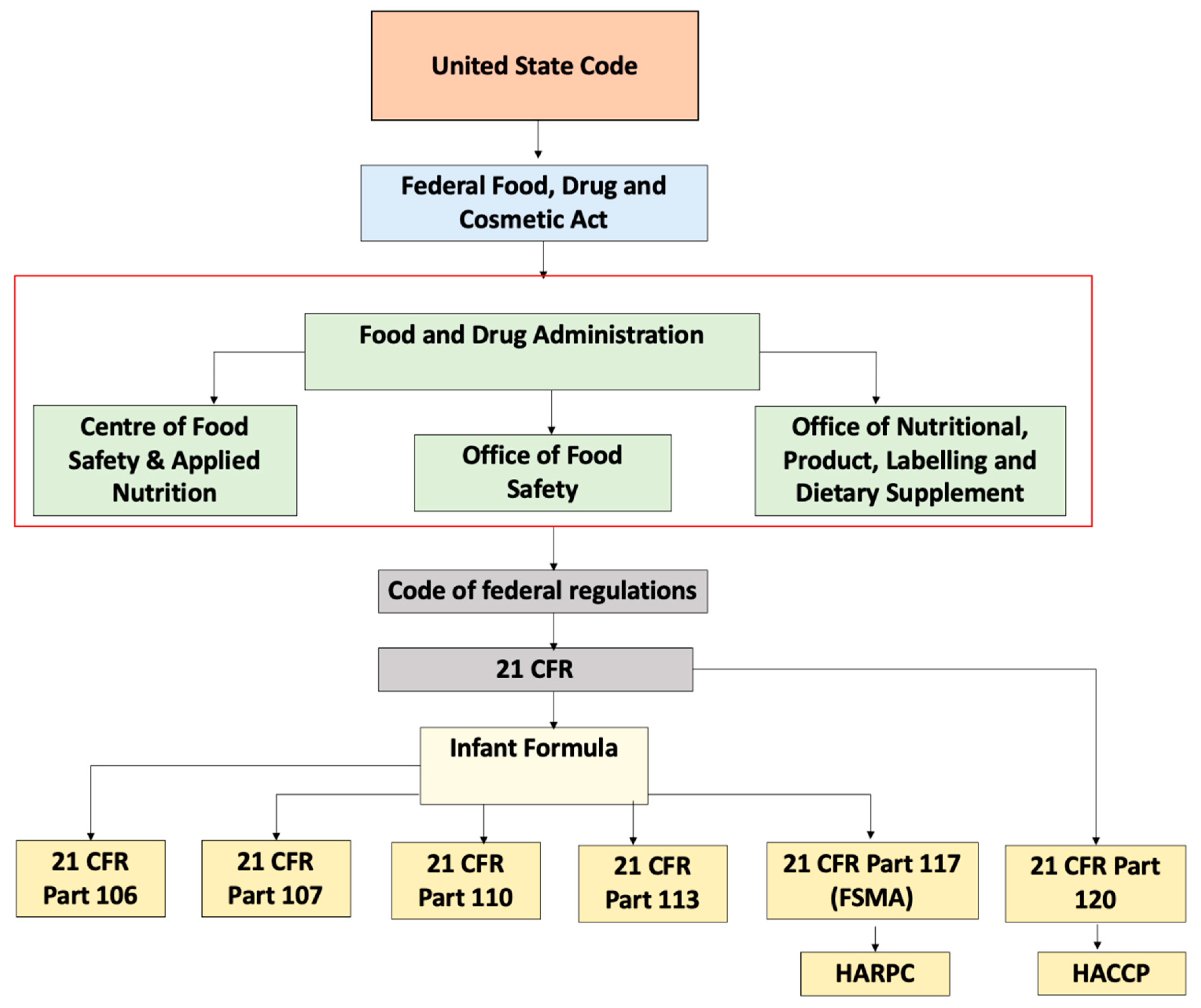

Whether or not HACCP for coffee roasting would require active verification of roasting temps, what about the overall HAPRC regulations? Generally, roasted coffee is low risk for contamination hazards, because it will normally (9/10 times) be brewed with near-boiling water, and also there is no real history of micro concerns. My questions is: would a HACCP plan be required, if the "cook step" is something that the product literally has to go through regardless, in order to be sold as roasted coffee? If so, would I actually need to verify the monitoring of that "cook step" for each batch? A coffee that has not reached the appropriate roasting temp (typically in excess of 300 degrees Fahrenheit) or the correct amount of time (anywhere from 12-18 minutes) will not appear properly roasted, or if it did, would not meet its taste profile during quality (sensory) checks. Our supplier suggested that they are therefore not responsible for any kind of FSVP requirement as of yet. Additionally, no one in our industry appears to know anything or be asking anything about pesticide residues. In discussions with one of our larger suppliers, I was told that the FSVP rule for green coffee importers was practically non-existent, as the food product is technically controlled downstream (by us) as far as microbiological concerns when it came to mycotoxins, there appears to be no actual regulatory limit within the US for coffee. We source Specialty Coffee exclusively however, the origins are drastically varied, from East Africa to Southeast Asia to a dozen countries in Central and South America.

We are NOT an importer ourselves, but work with 8-12 different midsize American importers of green coffee. One of my biggest challenges has been understanding supplier approval/verification, and how it applies to green coffee. Over the past 12-14 months, I've taken over the implementation of GMPs and the overall Food Safety Plan at a small-to-midsize coffee roaster in the Midwest USA.

0 kommentar(er)

0 kommentar(er)